CALL US NOW: 07531 812026

IMPACT MOLING

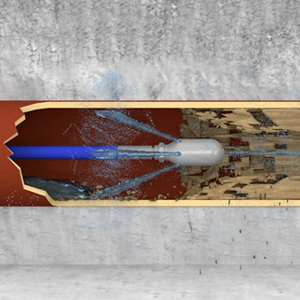

Impact Moling is used within the construction industry as a trenchless method used for laying pipes. During the moling process, a pneumatically driven solution known as a ‘mole’, forces its way through the soil along the desired path of the pipe.

This method avoids the need for digging trenches and can be used for laying various pipework.

AFRIEND DRAINAGE SERVICES IMPACT MOLES

- 50mm Diameter

- 75mm Diameter

- 100mm Diameter

- 150mm Diameter

AFRIEND Drainage Services can provide full comprehensive Impact Moling across the South of England. Please contact us for more information.

Impact moling is frequently used to install service pipes e.g. gas and water pipes to proprieties. This can be from an access chamber (see method below) or and excavation adjacent to a highway thus going under the road without the necessity for excavating a trench. Cables can also be installed using this method with or without ducting, although the provision of a duct is generally regarded as a safer method of cable installation and protection.

IMPACT MOLING METHOD

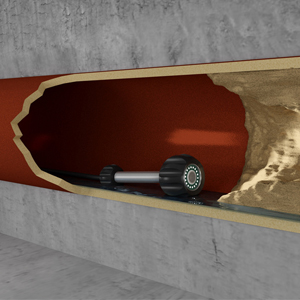

The standard approach to moling is to dig a hole about 1 m square and 2 m deep. Such a hole is small enough that it can be dug by hand instead of by machine in inaccessible locations. The mole is then entered into the earth on the horizontal face at the bottom of this hole. A destination hole of similar proportions is also dug, and this is where the mole emerges. The mole itself is a steel cylinder approximately 600 mm in length and can vary in diameter from 50mm to 150mm. It works as a pneumatic cylinder with pulsed compressed air causing the head of the mole to repeatedly hammer against the soil in front of the mole. Once the mole has passed through the earth the pipe can be pulled through the long horizontal hole.

Impact moles consist of an enclosed steel tube containing an air powered piston that strikes the nose of the tool driving it forward. A bore is formed by displacing and compacting the soil laterally. The friction between the ground and the mole body prevents the mole from rebounding backwards. Repeated impacts of the piston advance the whole unit through the ground. It is an untethered boring device. There is no rigid connection between the mole and the insertion pit, and the progress of the mole relies upon the frictional resistance of the ground for its overall forward movement.

CALL US NOW:

07531 812026